Welcome to Suzhou Casion International Trading Co.,Ltd.

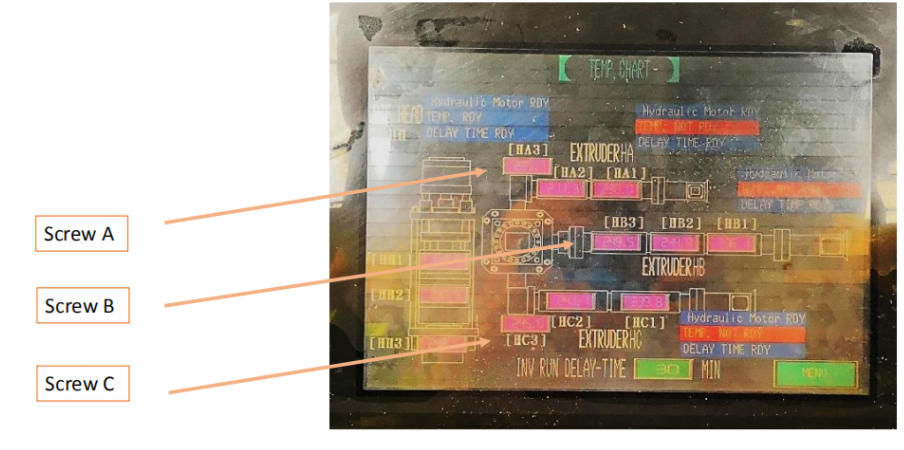

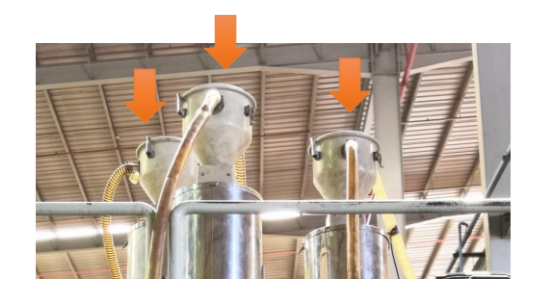

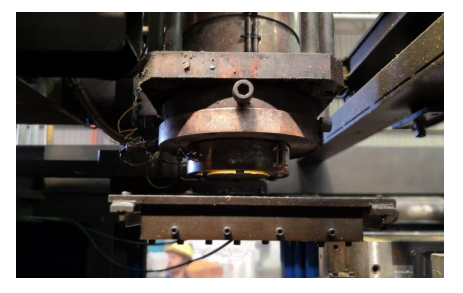

Screw cleaning

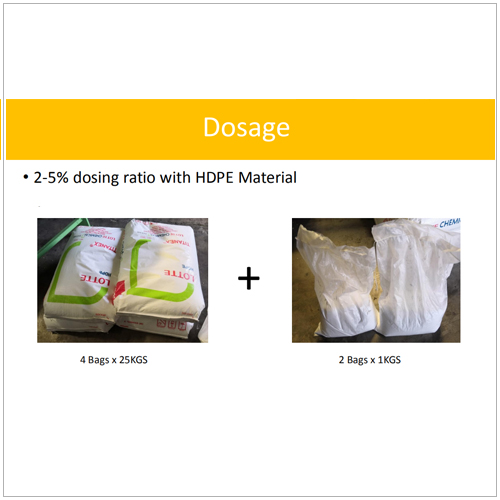

Dosage

·2-5%dosing ratio with HDPE Material

Example ∶

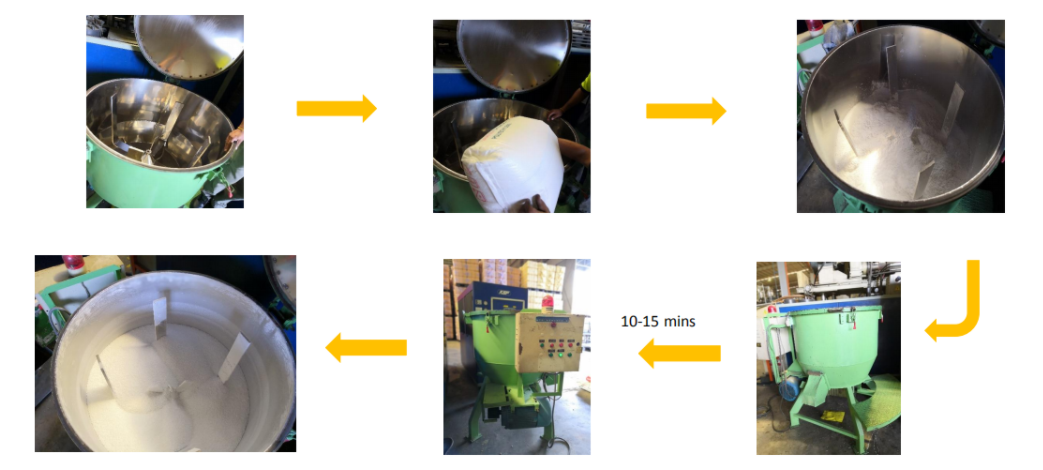

Purging Agent Application

Mixing

Direction of Use

1.Increase barrier melting zone&parisonhead temperature to 250 degree C.

2. Clear/take out the material from the hopper.

3.Loading mixture into individual screw accordingly.

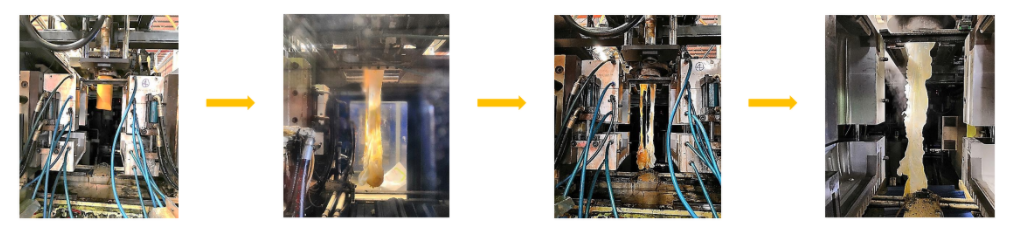

4. Purge the mixture material.

5.Hold the mixture material at screw for 1-2 hrs.

6.Add virgin HDPE material to hopper and continue to purge for around 10 minutes.

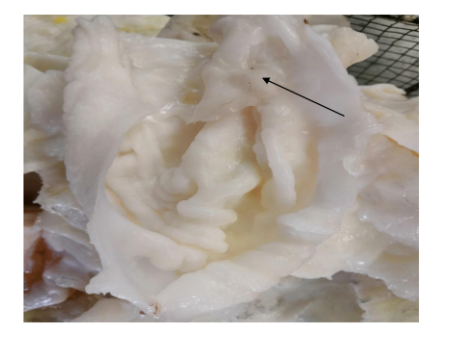

7.Material purged out should have foamed effect.

8.Material purged out should have foamed effect.

9.Material purged out should be natural white after the foam disappear, if slight color residue exists,continue to purge with virgin HDPE.

10.Should the color be very opaque or there is a lot of black carbon coming out, repeat the steps from step 4.

Write your message here and send it to us