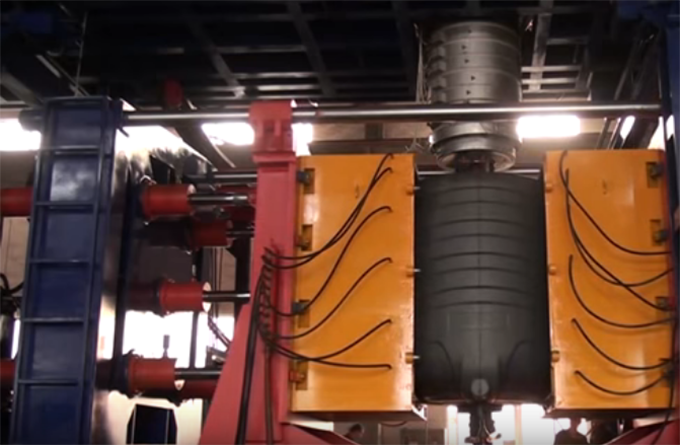

DK-2000USH-2000L (3-6Layers)

Big Water Mucket Blow Moulding Machine

Description of control system:

Siemens PLC of Germany is adopted, high reliable industrial man-machine interface is adopted. Chinese and English operation, action and fault monitoring and alarm functions. Focus on the version of software, system integration, reliable, error checking, maintenance simple. The operation is very convenient. The servo system adopts Japanese Moog 100 point controller. Equipped with high performance servo valve of Muge g631-3006b, imported electronic ruler closed-loop control. Real time response, precise and smooth control, curve tracking and feedback display function.

Hydraulic system:

The proportional energy-saving double pump control system is adopted. The hydraulic components are imported hydraulic directional valve and imported VQ35 super static oil pump. Japanese NOK seals are used. Aviation grade servo valve. The system has the advantages of energy saving, stability and reliability, fast reaction speed and long service life. Equipped with independent international standard servo oil source system.

Die head:

The first in first out runner structure is adopted to ensure the uniform strength after the melt converges. Extrusion speed: 2 -- 3kg / S (depending on the size of the die).

Materials: 38crmoaia, 42crmov and 35CrMo were made after heat treatment.

Extrusion system:

Screw diameter: 120mm, length diameter ratio: 24 / 1, barrel and screw material: 38CrMoAl a nitrided steel. The thickness of nitriding layer is 0.4-0.6mm, and the hardness is hv900.

Gearbox:

Hardened gear grinding reducer, 39 thrust inlet bearing.

Main technical parameters:

| Item | ||||

| Extruder | Four layers | 90/90/90/90MM | ||

| Five layers | 90/80/80/80/90MM | |||

| Six layers | 90/75/75/75/75/90MM | |||

| Machine die head | 100L accumulator type die head | |||

| Clamping Unit | 3 pieces type clamping unit with 2 pull bars | |||

| Machine Frame | machine frame with elevator | |||

| Material loader | Vacuum conveyor | 4 | ||

| Vacuum conveyor | 5 | |||

| Vacuum conveyor | 6 | |||

| Blow Unit | multifunction blow seat | |||

| Robert | adjustable robot | |||

| Hydraulic System | Delta servo main hydraulic unit and Wall thickness control small hydraulic unit | |||

| Pneumatic System | pneumatic control system | |||

| Electric System | Siemens PLC electric system | |||

| Power | Layers | Total power | Average consumption | |

| 4 | 404.5 | 220 | ||

| 5 | 441.5 | 230 | ||

| 6 | 478.5 | 240 | ||

| Machine Dimension (L x W x H) | 11*8*6.5M | |||

| Machine Weight | 50-70TON | |||

| Product Pange | 500-2000L Horizontal Tank and 2500L Vertical tank | |||

| Melting Capacity | 450 KGS / Hour | |||

| Layers | 4layers | 1-4 | ||

| 5layers | 1-5 | |||

| 6layers | 1-6 | |||

| Extruder | ||||

| Screw and Barrel | Screw Diameter | Four layers | 90/90/90/90MM | |

| Five layers | 90/80/80/80/90MM | |||

| Six layers | 90/75/75/75/75/90MM | |||

| Screw L/D | 30:1 | |||

| Screw Material | 38CrMoAl | |||

| Barrel Material | 38CrMoAl | |||

| Driving Motors and Inverter | Motor Brand | Siemens motor | ||

| Power | Four layers | 45/45/45/45KW | ||

| Five layers | 45/37/37/37/45KW | |||

| Six layers | 45/37/37/37/37/45KW | |||

| Inverter | ABB AC550 | |||

| Gear Box | Brand | GUOMAO | ||

| Hard Surface and Hardness | ||||

| Water Cooling Unit | Seperated heat exchanger | |||

| Temperature Control | Heaters | Cast aluminum heating ring | ||

| Heating Zone | Four layers | 20 ZONE | ||

| Five layers | 22 ZONE | |||

| Six layers | 26 ZONE | |||

| Heating Power | 54.5KW | |||

| Cooling Hoses Design | With manifold,tidy and won't block the way. | |||

| Cooling System | Barrel heating zone with cover and cooling fan, feeding zone with water cooling unit | |||

| Machine die head | |||

| Accumulator | Style | Accumulator model | |

| Volume | 100L/75KG | ||

| Material | 38CrMoAl & 45# steel | ||

| overflow hole | side mounted overflow hole | ||

| Material Pushing and Thickness Control Cylinder | Model | 2-in-1 cylinder for material pushing and thickness control | |

| Working Pressure | ≤16 mpa | ||

| Working Temperature | ≤70°C | ||

| oil temperature control unit | water-cooled plate,reduction of temperature,keeping cylinder working with good temperature | ||

| Die Pin and Core Pin | Material | 45# steel | |

| Size | Matching products | ||

| Temperature Control | Heaters Style | High efficient ceramic heating ring | |

| Power | Four layers | 64KW | |

| Five layers | 80KW | ||

| Six layers | 80KW | ||

| material feedin |