DK-250USH-250L

DK-250USH-250L

Extrusion Blow Moulding Machine

with an accumulator head

Description of control system:

Siemens PLC of Germany is adopted, high reliable industrial man-machine interface is adopted. Chinese and English operation, action and fault monitoring and alarm functions. Focus on the version of software, system integration, reliable, error checking, maintenance simple. The operation is very convenient. The servo system adopts Japanese Moog 100 point controller. Equipped with high performance servo valve of Muge g631-3006b, imported electronic ruler closed-loop control. Real time response, precise and smooth control, curve tracking and feedback display function.

Hydraulic system:

The proportional energy-saving double pump control system is adopted. The hydraulic components are imported hydraulic directional valve and imported VQ35 super static oil pump. Japanese NOK seals are used. Aviation grade servo valve. The system has the advantages of energy saving, stability and reliability, fast reaction speed and long service life. Equipped with independent international standard servo oil source system.

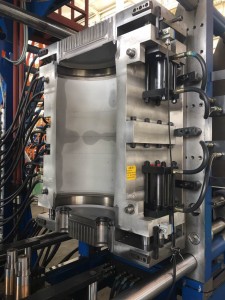

Die head:

The first in first out runner structure is adopted to ensure the uniform strength after the melt converges. Extrusion speed: 2 — 3kg / S (depending on the size of the die).

Materials: 38crmoaia, 42crmov and 35CrMo were made after heat treatment.

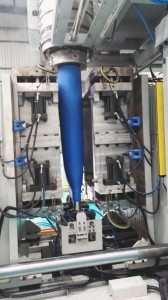

Extrusion system:

Screw diameter: 120mm, length diameter ratio: 24 / 1, barrel and screw material: 38CrMoAl a nitrided steel. The thickness of nitriding layer is 0.4-0.6mm, and the hardness is hv900.

Gearbox:

Hardened gear grinding reducer, 39 thrust inlet bearing.

Main technical parameters:

| Model | Unit | DK-250USH |

| Max .product volume | L | 250 |

| Dry cycle | pc / h | 900 |

| Main screw diameter | mm | 120 |

| Screw L/D ratio | L/D | 25 |

| Plasticizing capacity (HDPE) | Kg/hr | 350 |

| Heating section number | zone | 6 |

| Heating power | kw | 30 |

| Main motor power (Squeeze out ) | kw | 75 |

| Oil pump motor power (Servo motor) | kw | 45 |

| Wall thickness motor power | kw | 5 |

| Clamping force | kn | 700 |

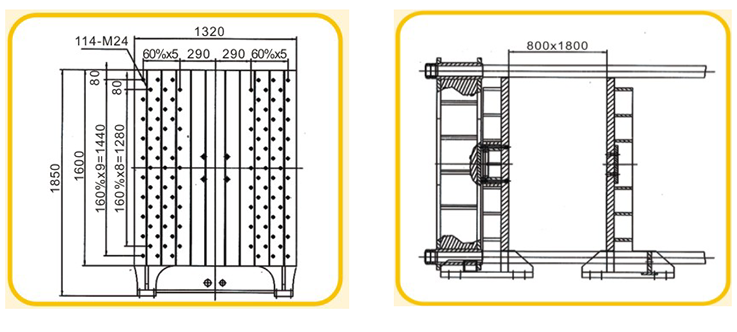

| Template spacing | mm | 800-1800 |

| Template size ( wide x high ) | mm | 1320×1850 |

| Heating power(Die head) | kw | 30 |

| Heating section number(Die head) | zone | 6 |

| Hydraulic system pressure | Mpa | 120 |

| Storage of material from die head | L | 25-40 |

| Air pressure | Mpa | 0.8 |

| Air emissions | m3/h | 120 |

| Cooling water pressure | Mpa | 0.3 |

| Cooling water discharge | t / h | 15 |

| Average energy consumption | kw | 75 |

| Total power | kw | 150 |

| Machine dimension(LxWxH) | m | 7.8×3.2×5.4 |

| Total weight | ton | 38 |