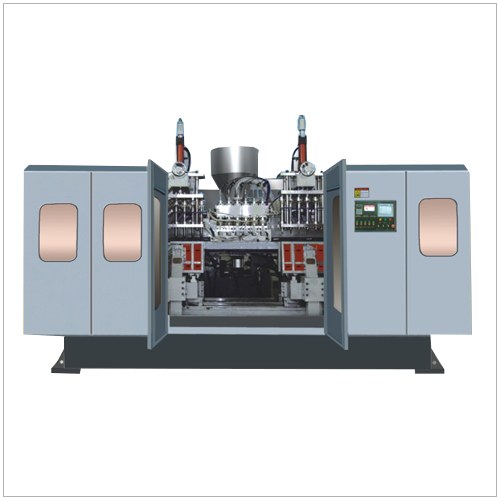

DK-75UF2x6-0.5L

DK-65UF2x6/75UF2x6

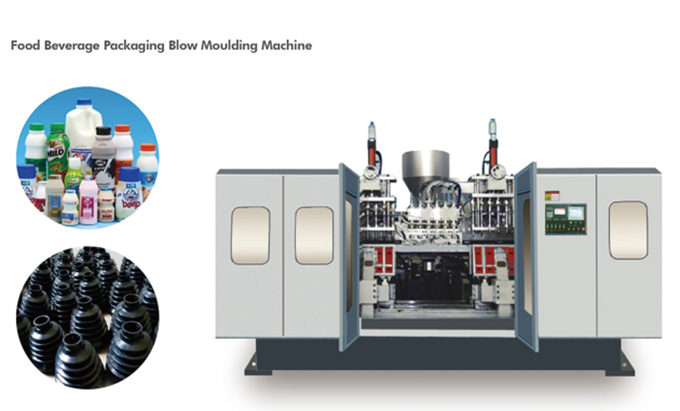

Bottles/bottle special Extrusion

Blow Moulding Machine(Single/Double Stage)

Technical Features:

Control system: full micro computer control plus color HIM touch paneling Chinese or English, combining special temperature control module.

Hydr aulic system: proportional control,equipped with imported famous br and

hydraulic components which en sure stability and reliability.

Pastieizing system: High plasticizing screwmade of quality steel 38CrMoALA by

nitriding treatment ensures uniformity of plasticization and color mixing.

Speed regulation: Gear box equipped withgear made of high strength alloy 20CrMnTi

plusinverter en sure stability of speed regu lation,low noise and durability.

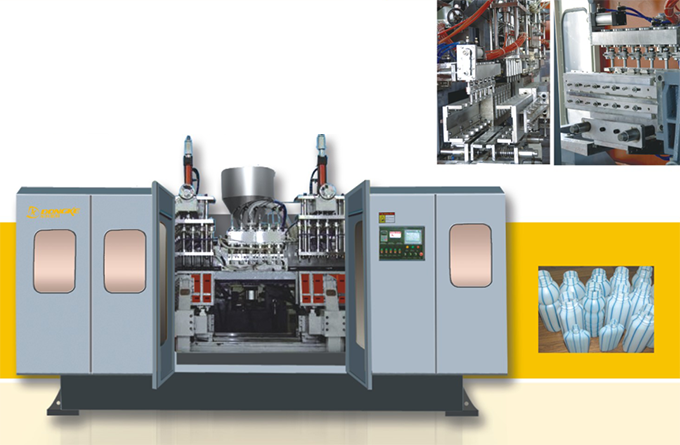

Clamping and mold movement: Pliers type clamping mechanism and linear rollers

guide rail for mold base motion result in energy saving and uniform and big clamping force. Stroke throttle in stalled under the base ensures smooth and quick movement.

Deflashing device: Optional deflashing devicecan be equippedin order to realize

automatic production and reduce labor cost.

Technical features:

Electronic control system: full computer control (Chinese or English), color full touch screen control, special computer temperature control module. Full computer type (1. Flow rate 2. Pressure 3. Temperature 4. Speed 5. Automatic calculation of output 6. Automatic reset 7. Automatic display of faults, etc. controlled directly by a computer)

Hydraulic system: proportional pressure control, equipped with imported famous brand hydraulic components, stable and reliable.

Plasticizing system: high quality 38CrMoAl a nitriding steel high plasticizing mixing screw to ensure full and even plastic color mixing.

Speed control system: imported variable frequency speed regulation + 20crmnt high strength alloy steel hard tooth surface reducer, stable speed regulation, low noise, durable.

Mold opening and closing system: double linear ball linear guide rail translational die, force amplification clamp type mold locking mechanism, energy saving, large clamping force, balanced, no deformation,

Stable and rapid mold moving hydraulic brake system, fast speed, accurate positioning, no impact.

It can be equipped with automatic water removing device to realize automatic production of products and reduce labor cost.

Main technical parameters:

| Model | Unit | DK-75UF2x6-0.5L |

| Max .product volume | L | 0.5 |

| Dry cycle | pc / h | 1000 |

| Main screw diameter | mm | 75 |

| Screw L/D ratio | L/D | 25 |

| Plasticizing capacity (HDPE) | Kg/hr | 120 |

| Heating section number | zone | 4 |

| Heating power | kw | 20 |

| Main motor power (Squeeze out ) | kw | 30 |

| Oil pump motor power (Servo motor) | kw | 15 |

| Wall thickness motor power | kw | 4 |

| Clamping force | kn | 400 |

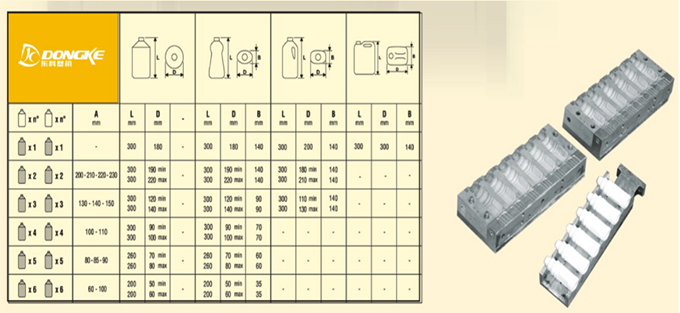

| Template spacing | mm | 130-330 |

| Template size ( wide x high ) | mm | 500x400 |

| Heating power(Die head) | kw | 15 |

| Heating section number(Die head) | zone | 8 |

| Hydraulic system pressure | Mpa | 120 |

| Storage of material from die head | L | |

| Air pressure | Mpa | 0.8 |

| Air emissions | m3/h | 60 |

| Cooling water pressure | Mpa | 0.3 |

| Cooling water discharge | t / h | 5 |

| Average energy consumption | kw | 25 |

| Total power | kw | 70 |

| Machine dimension(LxWxH) | m | 4.5x3.2x2.8 |

| Total weight | ton | 11 |